Cold Chain Logistics and the Stakes at Hand

In today’s global supply chain, cold chain logistics plays a critical role in the safe transport of temperature-sensitive goods. These products range from fresh produce, frozen food, and seafood to high-value items like pharmaceuticals, vaccines, and hazardous chemicals. For shippers, retailers, and manufacturers alike, maintaining strict temperature control from origin to destination is not optional—it’s required.

Just a few degrees off, even for a short time, can spell disaster. Temperature deviations during transit or cold storage can compromise product quality, trigger spoilage, lead to load rejections, and erode customer trust. In industries where regulatory compliance and safety are tightly monitored, there’s no room for error.

This is where real-time monitoring becomes a game-changer. It gives both carriers and shippers the ability to monitor temperature, humidity, and other environmental conditions continuously, and act the moment anything goes out of spec. It’s about protecting cargo and building trust through data, transparency, and fast decision-making.

The Cold Reality: What Happens When Temperatures Shift

When it comes to temperature-sensitive cargo, failure doesn’t always look like broken equipment. Sometimes, it’s as simple as:

- A trailer door left open during a handoff

- A reefer unit failing to maintain the required temperature overnight

- An overlooked setting on a load of deep-frozen pharmaceuticals

- A shift in ambient humidity while docked at a storage facility

These minor slips can cause major consequences—especially in the cold chain. Unlike other freight, cool cargo cannot afford inconsistencies. Fruits, vegetables, meat, seafood, and dairy can spoil quickly. Vaccines and biologics can lose potency. Chemicals may react dangerously if not kept stable.

And in many cases, the damage isn’t discovered until the cargo arrives—by then, it’s too late.

The result? Lost revenue, product spoilage, regulatory fines, disappointed customers, and permanent damage to brand reputation. These risks are why more companies are turning to advanced temperature monitoring systems to close the visibility gap in their cold chain management.

How Real-Time Monitoring Protects the Cold Chain

Modern real-time temperature monitoring involves a combination of wireless sensors, cloud-based dashboards, and integration with refrigerated trucks and refrigeration units (like those from Thermo King). Together, they offer live, accurate, and constant data reporting that follows the shipment every mile of the way.

Here’s how it works:

- Temperature sensors are placed within the trailer or cargo hold, tracking internal conditions at set intervals.

- This data is transmitted wirelessly to a centralized platform.

- If there’s a temperature fluctuation, an automatic alert or clear alarm is triggered.

- Designated team members receive an instant notification and can act before damage is done.

These systems can even be configured with custom thresholds to align with specific cargo needs, like ultra-low temps for deep freeze vaccines or stable ambient ranges for chemical drums.

Beyond internal teams, many platforms also offer remote visibility to shippers. With access to temperature records, temperature history, and live updates, shippers can verify compliance, eliminate disputes, and gain peace of mind.

Remote Visibility: Building Trust Across the Supply Chain

In the past, temperature data was often collected manually, if at all. Drivers might write down reefer settings at intervals or note when the trailer was opened or closed. This paper trail was unreliable, time-consuming, and offered little assurance to shippers or regulators.

Today, those expectations have evolved. Real-time data is no longer a bonus—it’s a requirement for doing business with many customers. Shippers want to know:

- Was my cargo stored and transported within the right temperature range?

- Did any fluctuations occur during transit?

- Were there any automatic alerts, and how were they handled?

- Can I see the temperature history of my shipment across each leg of the journey?

Visibility into these details fosters trust, enables smoother communication, and helps resolve conflicts before they escalate. If something does go wrong, the data can serve as proof of action or provide insight to improve processes.

Why Temperature Monitoring Is a Win-Win for Carriers and Shippers

For carriers, investing in real-time monitoring technology offers tangible benefits beyond customer satisfaction. It helps:

- Prevent load rejections by catching issues early

- Reduce insurance claims related to temperature-sensitive cargo

- Minimize equipment downtime with health checks and diagnostics

- Build a reputation for reliability and compliance

- Create new revenue streams by offering premium cold chain services

For shippers, working with a carrier who uses real-time monitoring tools translates into more consistent service, less guesswork, and better data to back up quality and safety claims. It also helps them meet their own regulatory compliance obligations, especially when transporting pharmaceuticals, perishable goods, or hazardous materials.

Cold Chain Use Cases: Real-Time Monitoring in Action

Let’s break down some of the ways temperature monitoring systems deliver value across different types of cargo:

1. Fresh Produce and Perishable Foods

Fruits and vegetables are incredibly sensitive to temperature and humidity. Even brief exposure to the wrong conditions can lead to spoilage, ripening issues, or bacterial growth.

Real-time monitoring allows carriers to catch deviations early, especially helpful when dealing with long-haul routes or complex distribution paths involving multiple stops.

2. Meat and Seafood

These goods are often transported frozen or in highly controlled environments. Without stable temperature control, they can thaw, refreeze, or spoil quickly.

Automatic alarms triggered by temperature fluctuations allow teams to act before the product is compromised.

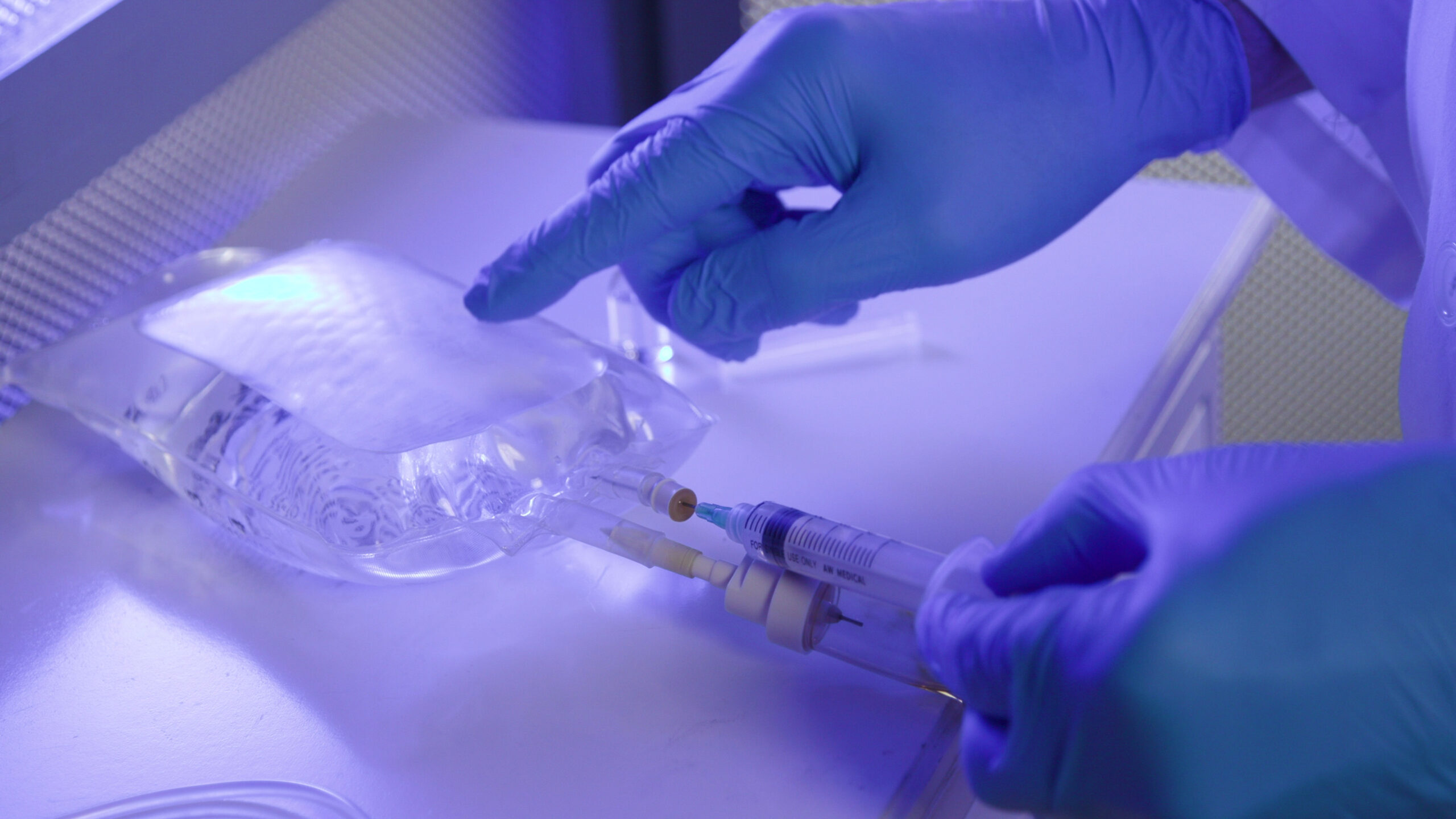

3. Pharmaceuticals and Vaccines

Few industries require more precision than pharmaceuticals. From deep freeze biologics to controlled ambient conditions, temperature stability is vital for preserving drug efficacy.

Having a complete temperature history, supported by real-time monitoring, is essential to meet regulatory standards and retain shipment value.

4. Chemicals and Hazardous Goods

Temperature-sensitive chemicals may become unstable or pose risks when exposed to the wrong environmental conditions. Live monitoring helps protect people, assets, and the integrity of your operations.

In these scenarios, real-time monitoring isn’t just a convenience—it’s a compliance necessity.

Technology That Powers the Cold Chain: Precision Reefer Solutions

At Precision Reefer Solutions (PRS), we provide advanced tools that bring visibility, control, and peace of mind to every cold chain shipment. Our technology connects directly with Thermo King and other popular refrigeration units to enable smarter cold chain logistics.

Here’s what our system offers:

- Live monitoring of temperature, location, and equipment status

- Automatic alerts when thresholds are breached

- Intuitive dashboards for internal teams and shippers

- Easy access to temperature records and compliance reporting

- Full control and visibility en route, from anywhere in the world

Our goal is to simplify the process of cold chain monitoring while increasing accuracy, accountability, and efficiency. Whether it’s a reefer trailer in motion or a storage facility in holding mode, PRS keeps your team in the know.

The Importance of Cold Chain Compliance

Failure to maintain temperature control can have legal consequences, especially in food, pharma, and chemical industries. Regulatory compliance demands clear documentation of storage conditions, especially when dealing with temperature-sensitive or hazardous cargo.

By automating the process and providing verifiable temperature history, PRS helps your business:

- Stay compliant with FDA, USDA, and international guidelines

- Streamline audits and reduce documentation stress

- Avoid penalties or load rejections due to incomplete records

- Build a stronger reputation with oversight agencies and clients

The ability to maintain precise conditions across cold chain logistics isn’t just about product protection—it’s about risk reduction at every step.

Building Long-Term Trust in Cold Chain Management

Trust is earned through consistency. Consistency is made possible through real-time data, automated systems, and people who act on it.

For shippers, knowing that their cargo is being monitored 24/7 builds peace of mind. For carriers, having the data to prove quality, compliance, and proper handling builds credibility and long-term customer loyalty.

In the increasingly competitive world of cold chain transportation, the companies that win are the ones that can show, not just say, they’ve got it under control.

Ready to Trust the Temp?

From reducing product spoilage and increasing efficiency to meeting strict regulatory compliance requirements, real-time temperature monitoring is the backbone of modern cold chain management.

With PRS, you gain:

- Continuous real-time data

- Alerts for fast intervention

- A clear record of compliance

- Tools to build stronger relationships with your clients

Whether you’re shipping meat, seafood, vegetables, pharmaceuticals, or chemicals, the path to reliable service starts with the right systems. At Precision Reefer Solutions, we help you deliver the cold chain confidence your business and your customers demand.

Cold chain success comes down to one thing: trust. And with PRS, that trust is built in, every step of the way. Book a demo today!