Why Cold Chain Matters in Pharma

In the pharmaceutical industry, protecting temperature-sensitive products is essential to product quality and patient safety. The pharma cold chain is key to this process, ensuring products stay within the required temperature range from production to delivery. As the pharma supply chain gets more complex and demand for advanced therapies and biologics grows, temperature control has never been more important. One lapse in the cold chain can compromise a product’s efficacy and result in big financial losses and patient harm. With so much at stake, cold chain is no longer optional – it’s fundamental to the modern supply chain.

Temperature Sensitivity in Pharma

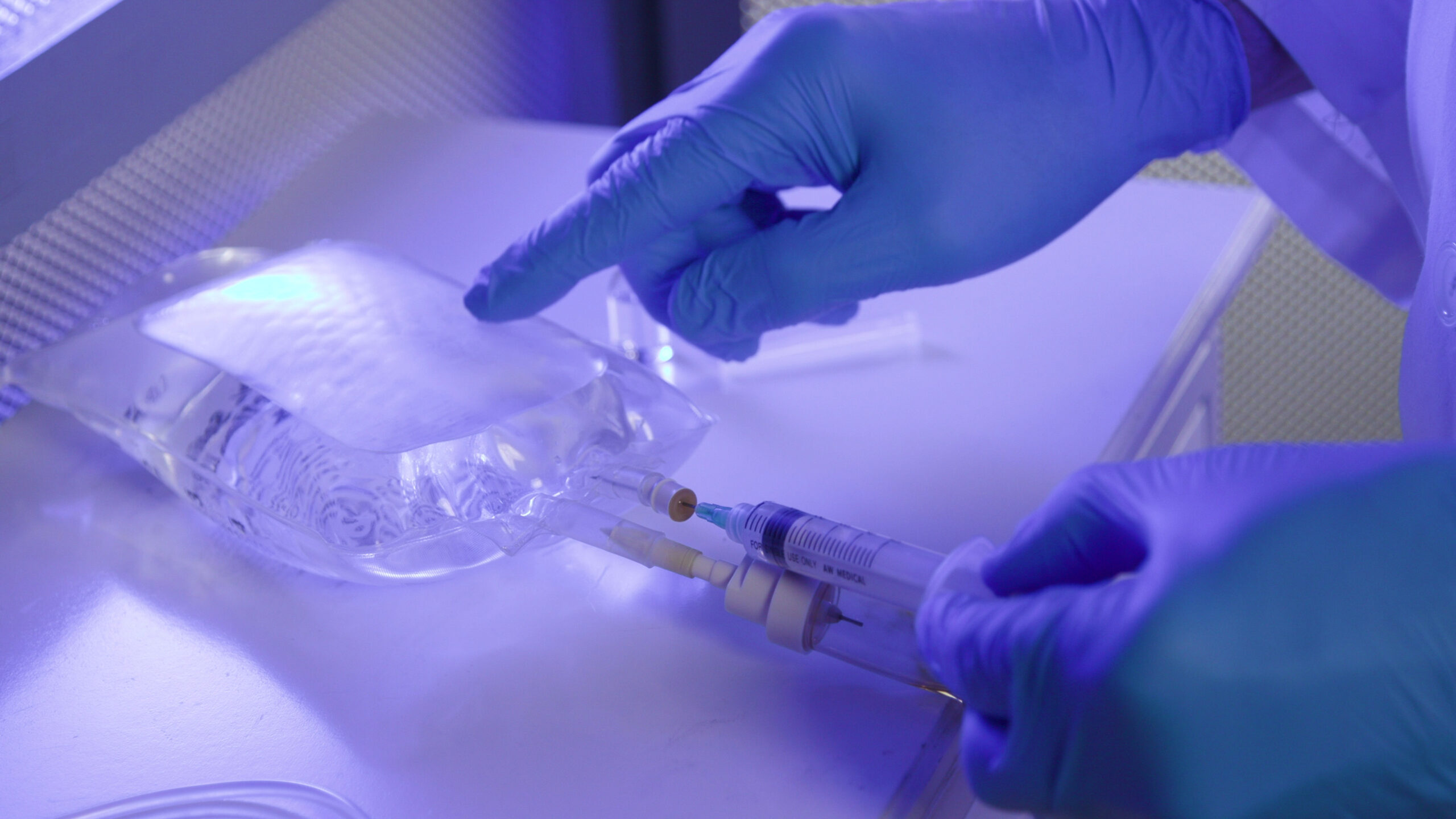

Many pharmaceutical products are sensitive to even small temperature fluctuations. These temperature-sensitive medications require temperature control throughout shipping and storage to maintain therapeutic properties and patient safety.

Common temperature-sensitive pharmaceuticals include insulin, vaccines, some cancer treatments, and biologics – all of which must be stored and transported within specified ranges to remain effective. For example, many vaccines must be kept between 2°C and 8°C, and some advanced therapies require frozen or ultra-low temperature conditions.

When temperature excursions happen – such as exposure to temperatures outside the specified ranges – the product integrity can be compromised. This not only affects the medication’s efficacy but can make it unsafe for use, putting patient health at risk and resulting in product losses. For pharma, understanding and managing these risks is key to protecting patients and the supply chain.

Components of Cold Chain Management

Cold chain management is a highly coordinated system that protects temperature-sensitive medications from manufacture to patient delivery. From the moment a product is created, it enters the cold chain – a tightly controlled process that includes temperature-controlled storage, secure packaging, and specialized transportation. Successful cold chain management relies on seamless coordination between pharma companies, logistics providers, and storage partners. Each link in the chain is responsible for shipping pharmaceuticals and storing pharmaceuticals in the right conditions to maintain product integrity.

At the heart of this is cold chain logistics, which includes refrigerated trucks, cold rooms, and temperature-controlled containers, along with constant monitoring throughout the journey. A reliable cold supply chain is not just about temperature control – it’s about end-to-end visibility, accountability, and consistency across the entire process.

Technologies for the Cold Chain: Monitoring, Packaging & Control

Technology has become essential for protecting temperature-sensitive pharmaceutical products. Real-time temperature monitoring allows for immediate visibility into a shipment, to maintain a consistent temperature across the supply chain. This real-time visibility is key to protecting product quality during transit and storage.

Modern cold chain monitoring systems use advanced temperature monitoring devices that collect and transmit temperature data. These tools can detect and alert teams when a shipment identifies temperature variations, so you can prevent temperature excursions before they impact internal temperatures or product integrity.

Temperature mapping is also used to validate that all areas of a storage or transport unit are within the required ranges. Combined with predictive analytics and data analysis, you can spot potential risks before they become big problems.

Packaging is also key. Today’s thermal packaging solutions include various packaging systems to maintain temperature control. These may involve vacuum-insulated panels, phase change materials that regulate thermal conditions, or liquid nitrogen systems for ultra-cold shipments. Together these technologies keep conditions safe from the warehouse to the delivery point.

Regulatory Compliance & Quality Assurance in the Pharma Cold Chain

Regulatory compliance is non-negotiable in pharmaceutical cold-chain operations. Industry standards such as GDP and cGMP set strict guidelines to protect temperature-sensitive pharmaceuticals throughout storage, transport, and handling. To meet these requirements and comply, companies must have robust quality management systems that monitor every step of the cold chain process. These systems track operational consistency and data integrity – all temperature records, alerts, and logs must be accurate, auditable, and tamper-proof.

Beyond systems and technology, comprehensive training programs are essential. Every stakeholder – from warehouse staff to transport partners – must understand their role in compliance. Ongoing education and continuous improvement help teams stay up to date with changing regulations and best practices, ultimately strengthening the entire cold chain.

Managing Risks in Different Environments

Temperature-controlled pharmaceutical shipments face many external challenges that can compromise product safety. Different environmental conditions – from extreme heat to freezing temperatures – can affect shipments in transit or storage. These risks are heightened when external power is disrupted or unavailable, especially during long hauls or delays.

Proper storage is key across all environments. During air transport, cargo is exposed to changing temperature conditions at different altitudes and tarmac delays. Cold rooms and storage facilities must be equipped to provide consistent refrigeration even in case of power fluctuations or climate-related challenges.

To reduce the risk of temperature deviations, pharmaceutical companies, and logistics providers use multiple layers of protection to maintain the desired temperature for extended periods. This includes validated packaging, reliable equipment, backup power solutions, and routing strategies to minimize exposure to environmental extremes. Together these approaches keep product integrity no matter the journey.

Future of Pharmaceutical Cold Chain Solutions

As the pharmaceutical industry evolves, so do the demands on the pharma cold chain. New therapies, biologics, and personalized medicine require even tighter controls and more specialized handling. To meet these emerging needs pharma cold chain solutions are being redefined by innovation.

Technologies such as real-time temperature data collection and advanced analytics are providing deeper insights into every shipment, so pharmaceutical companies can respond to issues in real time and predict and prevent future risks. These innovations protect temperature-sensitive pharmaceutical products better and safer. Select logistics providers with the right tools, expertise, and infrastructure to protect products. A good partnership means products arrive safe, within spec, and with therapeutic properties intact – no matter the journey.